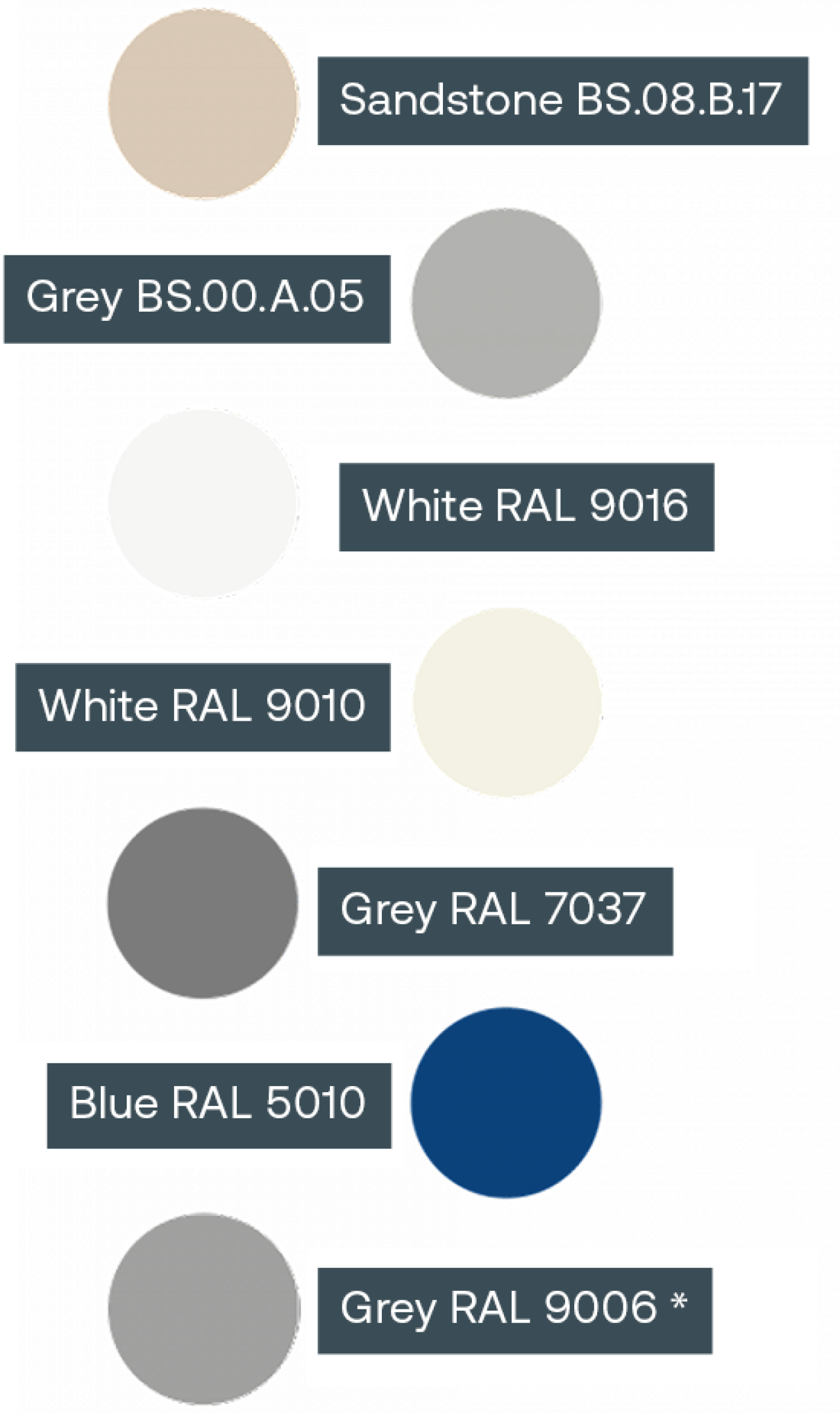

Titan Colour Finishes

We always prepare our products to the highest quality. All panels come with a TGIC and lead-free powder coat which is an average thickness of 70 microns.

Non-standard and corporate colours are also available, as well as anti-static/electro dissipative and antimicrobial powder coatings.

Please get in touch if you have any questions.

* RAL 9006 available at an extra cost

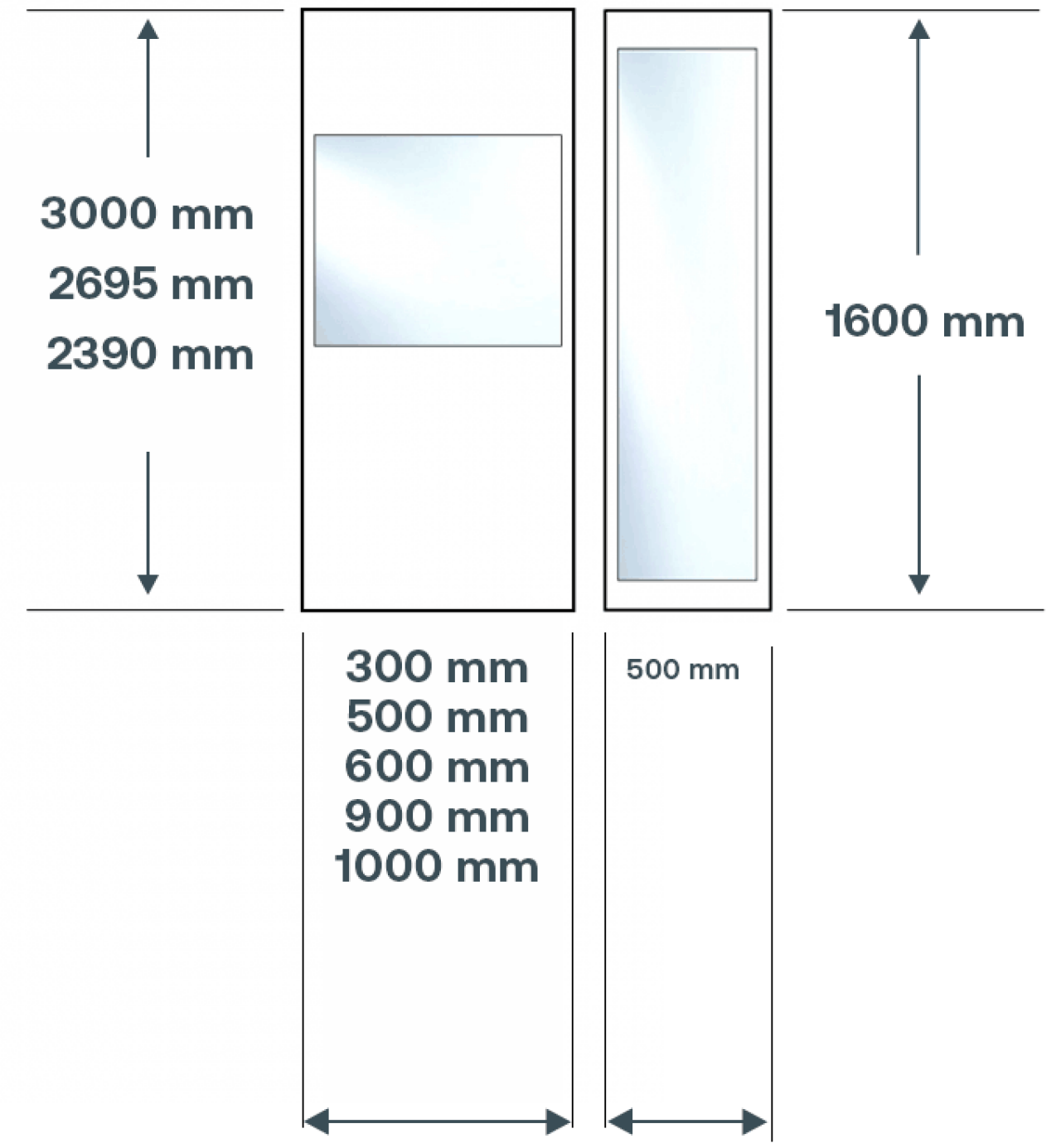

Titan Panels

AS (all steel) and SGS (steel-glass-steel) cleanroom panels all come in the standard sizes shown.

AG (all glass) panels come in a standard glass size of 500 mm x 1600 mm, and a steel frame of the desired height and width.

Our Process

Starting a project can seem like a daunting prospect so we’ve made the process as simple and reassuring as possible to ensure minimal impact to your existing workflows.

Survey & Consultation

Ideally, we begin with a survey of your premises, enabling us to see how you work, take measurements and discuss different options in person with you. However, if this isn’t possible then we can normally gain most of the information needed over the phone.

Proposal

Following on from the site survey we will deliver our proposal & recommendations based on your requirements and anticipated future goals.

Design

Based on the agreement of your proposal we begin the final design process, submitting detailed drawings for your approval and sign off.

Installation

Each project has a dedicated project manager who will work with you to plan dates and to provide you with H&S documentation. Our qualified installation teams will then complete the project.

Handover

We pride ourselves on the quality of our products and installations. We handover each project with all relevant documentation, training and certification.

Talk to our storage experts

Our expert team are on hand and available to answer your queries weekdays until 5:30pm.